|

|

| Bikes - Talk & Issues Newsworthy and topical general biking and bike related issues. No crapola! Need Help: Try Searching before posting |

|

|

|

Thread Tools |

|

|

#11 |

|

Noisy Git

Mega Poster

Join Date: Apr 2007

Location: Halifax/Leeds

Posts: 26,645

|

The bottom of the valve is supposed to touch the head!

The shims don't wear, the head does. When the valve seat in the head wears, the clearance gets smaller. Hydraulic tappets on motors, they effectively get thinner so they lose oil pressure inside which allows the clearance to become too big, hence the tappety ticking. Personally I check my own valves more often than book, it's got hotter cams in. Even with the stock cams the first time I checked it I found, no sh*t, 7 of 8 valves to be too tight.

__________________

Currently Ex Biker

Now rebuilding a 63' fishing trawler as a dive boat |

|

|

|

|

|

#12 | |

|

Guest

Posts: n/a

|

Quote:

I didn't realise the valve actually rested in the valve seat when closed. I thought there was a clearance between the two, and as it wears it was that clearance that got too tight. i.e. the flat bottom of the valve supposed to sit in the aperture hence closing the port, and the curved bit behind that effectively suspended within the valve seat, on the shaft of the valve, with a clearance between valve and seat. |

|

|

|

|

#13 |

|

Noisy Git

Mega Poster

Join Date: Apr 2007

Location: Halifax/Leeds

Posts: 26,645

|

Sorry no offence meant, for change

__________________

Currently Ex Biker

Now rebuilding a 63' fishing trawler as a dive boat |

|

|

|

|

|

#14 |

|

Guest

Posts: n/a

|

OK, yeah I get it. It would have to be that way due to the kind of compression in the cylinder right enough. If the valve mechanism left a small clearance, and the compression pushed the valve into the seat, that would be putting an undue strain on the valve mechanism. The valve has to sit in the seat and the tension between cam and valve released, before the fuel explodes. One of these days I'll have reason to take the head off an engine and have a play. You can't properly understand these things by reading about it. Last edited by -Ralph-; 02-02-12 at 11:21 AM. |

|

|

|

#15 |

|

Noisy Git

Mega Poster

Join Date: Apr 2007

Location: Halifax/Leeds

Posts: 26,645

|

If you are passing I have some in bits.

Reason for clearance is heat, exhaust valve has 900C gas going past it 5000 times a minute, it needs to be touching head so all that heat can be removed by all the water circulating round the head. Otherwise valve can burn up.

__________________

Currently Ex Biker

Now rebuilding a 63' fishing trawler as a dive boat |

|

|

|

|

|

#16 | |

|

Member

Mega Poster

Join Date: Dec 2007

Posts: 2,708

|

Quote:

Firstly (and secondly), I said the first clue to valves being out is an uneven idle. I didn't say and uneven idle was caused by incorrect valve clearances, as you say it can have several causes, but you try and get a bike with tight valves to idle evenly. If the bike still idles smoothly your valves are unlikely to be far out. Again, a rattle may not be down to valve train, but if you do have a rattle it would be one of the first things to check. Thirdly, I did say the dealer stamps might be important to him, but thanks for explaining why. Finally (oh I wish) how do you know I don't ride bikes that are serviced with a slavish devotion to manufactures schedules? For the record I do, and you would not believe the number of times they've told me such and such can't need attention because it's not due for x number of miles.... hence my comment that anyone with even a little mechanical savvy should be able to tell when something needs looking at. Just use some common sense about it and apply some thought about how you use the bike. If I "serviced" my track bike at manufactures recommended intervals I'd have no brakes by April and a blown engine by June. Likewise someone commuting up and down the motorway every day is going to get pretty fed up with going to his dealer every 600 miles to gets his chain oiled and pads checked. |

|

|

|

|

|

|

#17 |

|

Member

Mega Poster

Join Date: Jul 2003

Location: Warwickshire

Posts: 2,804

|

Might be worth a few notes here on valve train stuff, it's what I do for a living (some of the time!).

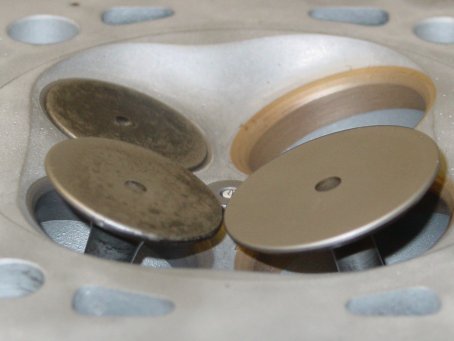

Here's a picture of half a typical cam profile, the other half would go from 0 to plus 80deg or so.  The lift curve itself doesn't really tell you very much about the dynamics, the velocity, acceleration and jerk contain more critical stuff. In mathematical terms, if you differentiate lift you get velocity (rate of change of lift), differentiate again and you get acceleration (rate of change of velocity), and again you get jerk (rate of change of acceleration). Note the values are in terms of cam degrees, so velocity is "mm/deg" or similar (inches/deg shown in the diagram), so in absolute terms the actual velocity is proportional to engine speed, acceleration to speed squared etc. You'll notice the first part of the lift curve is termed "ramp". This is where the valve clearance is gradually closed up and the cam starts to load up the valve train to overcome the spring seating load. Ramps are usually (not always) "constant velocity" so the rate of increase in loading is controlled during opening and also on the closing side the seating velocity is controlled to a reasonable value. This controls seat wear rates. When closed the valve spring holds the valve firmly onto the seat to ensure gas sealing but also good heat transfer (as YC said). Seating load is a compromise, too little and the valve gets hot, leaks, and also deposits can build up so causing compression problems (bad starting etc), too much and there's excess friction and wear etc. With bucket followers, the velocity tells you the "eccentricity" of the cam contact from the valve centreline, the further the contact from the centreline the faster the valve moves as the cam rotates. This determines the requires bucket diameter for example to avoid the contact running off the edge. It also significantly affects lubrication. The acceleration determines the required spring loads, the greater the negative acceleration over the peak the more spring load is required for a given total mass. Interestingly a poorly designed cam profile can result in the critical point being well away from the peak itself (for example around 30deg on the diagram), and then you end up with much higher peak loads than actually necessary if the acceleration curve was better designed, so more wear and friction. Note that actual acceleration is proportional to speed squared, so going from say 10k rpm to 11k rpm requires 121% of the spring load, thus loss of valve control tends to happen quite suddenly, and also means that it's not a good idea to exceed design speeds. The jerk describes how abruptly the acceleration changes, and can be likened to impact. This can lead to noise, unnecessary vibrations, wear etc. This would all be simple were it not for the fact that everything is flexible, and the whole system vibrates. This means that the actual forces aren't what the simple model suggests, which is where the experts come in. One major consideration is the spring, which tends to vibrate quite a lot on its own. Valve springs are often designed with essentially two rates (the coil winding is closer at one end so the coils close up as it is compressed and effectively become solid). The transition is usually designed to be at a length just shorter than the installed length so when the valve is on its seat most of the coils are active and the natural frequency is relatively low, then as it lifts the coils close up leaving fewer active coils and the nat freq increases significantly. The higher nat freq helps cut down the vibration response in itself, but also when the valve closes again the vibration frequency changes from high to low and this dissipates energy so the vibration damps out quite quickly. There are other things too.

__________________

"Artificial Intelligence is no match for natural stupidity" |

|

|

|

|

|

#18 |

|

Member

Mega Poster

Join Date: May 2005

Location: Sunbury Middlesex

Posts: 1,396

|

Good morning all.

This old can of worms again! I agree with Lozzo, in saying it's important to get the valves checked at the specified intervals. Roughly 50% of bikes that I service need valves shimming at the aforementioned specified intervals. Hornet 600's rarely need it doing at 16k, but often do at 32k. I would disagree with them saying it needs a new gasket. Providing the gasket hasn't gone hard, it's cleaned thoroughly, & a smear of good quality RTV is used around the camshaft cut outs it should be fine. Cheers. |

|

|

|

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Decision of the Day... | fenjer | Idle Banter | 27 | 22-04-11 06:53 PM |

| decision | the_other | Soho Massive | 25 | 07-08-08 09:36 PM |

| Camera decision | Ed | Idle Banter | 15 | 08-06-07 10:33 AM |

| Decision time, please help | linco | Idle Banter | 45 | 20-10-06 04:10 PM |

| Ive made my decision... | Jebiah | Bikes - Talk & Issues | 4 | 07-06-06 08:44 PM |