|

|

|

|

#11 | |

|

Member

Join Date: Jul 2009

Location: Guildford, surrey

Posts: 785

|

Quote:

Im glad someone said what alot of us are thinking

__________________

Was SV650S K9 Now GSXR 600 K9 |

|

|

|

|

|

|

#12 |

|

Member

Join Date: May 2012

Posts: 318

|

Which bit is causing you problems?

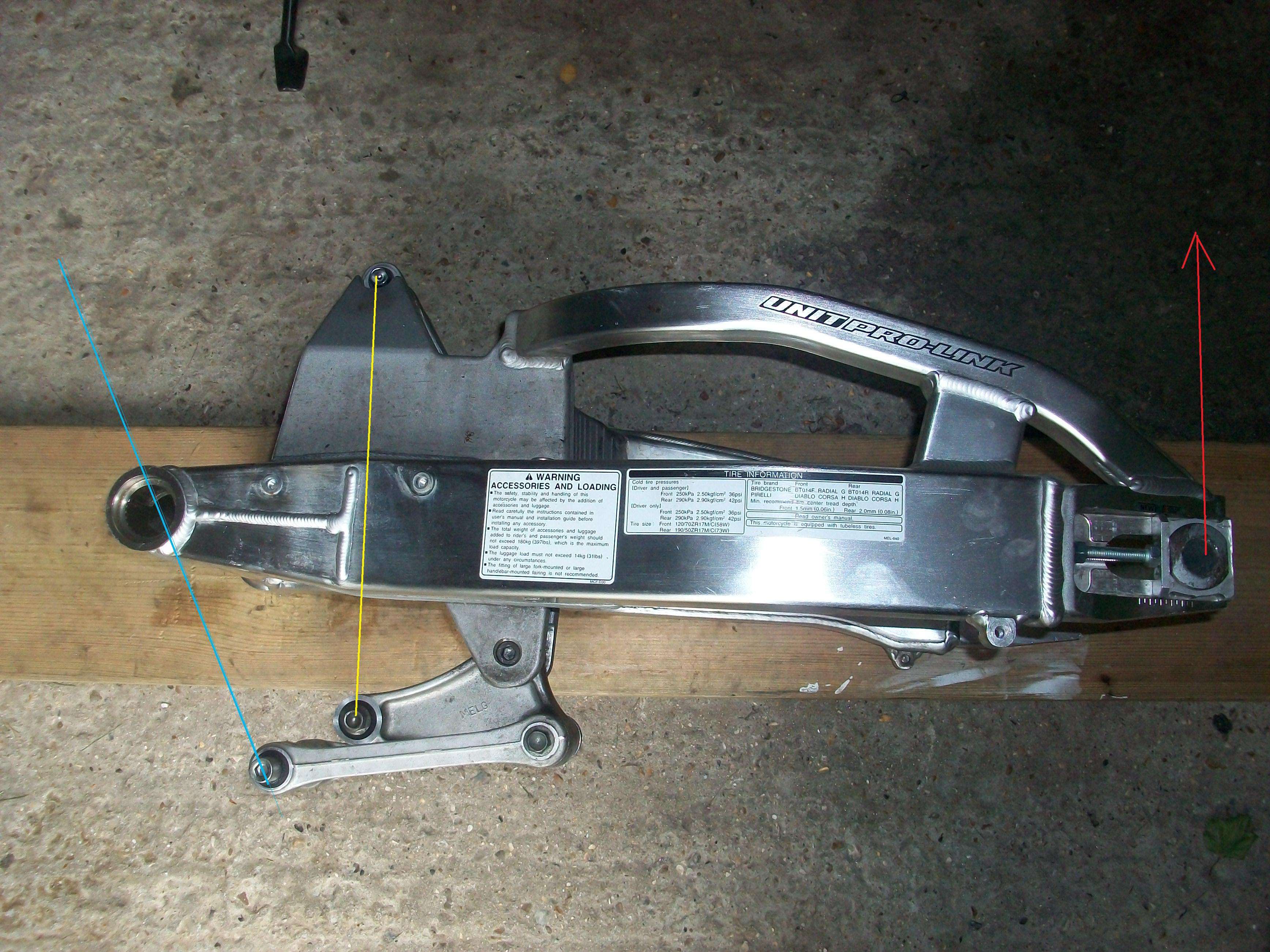

5083 is grade of aluminium that can be welded to Japanese production frames and doesn't need heat treating afterwards (tempering) to recover any strength lost by the heating from welding. EN24T is a grade of high tensile steel suitable for axles and pivots. The bearing tube is the tube at the front of the swingarm that has the swingarm pivot bearings in it and the rest of the swingarm is welded to it. The CBR suspension linkage works as shown in the picture below...  The blue line represents the frame - the swingarm pivot and linkage tie point are the only two points where the swingarm and rear suspension is attached to the frame. The red line represents the rear suspension being compressed. The yellow line shows the rear shock between the lower and upper mounting points. As the swingarm arcs upwards (red line) the lower shock mount is pulled upwards and compresses the rear shock. The top shock mount is also moving upwards but the leverage ratio of the CBR rear suspension is higher than a conventional rear suspension; 3.5:1 vs 2.4:1 typically, so rear wheel travel is the same as on any other bike. The advantage is that there's no top shock mount on the frame to try and line up - you've only got to get the linkage tie point lined up and it's an area of the frame where there is likely to be more space and material to work with. Last edited by millemille; 02-06-12 at 09:50 AM. |

|

|

|

|

|

#13 |

|

Guest

Posts: n/a

|

That bit...!!

Still at the point of coming to grips with basic bike maintenance, so even that explanation passed me. BUT - and it's a big one - I get PICTURES. Love a good picture story me, and one of a rebuild/upgrade/tinkerfest would be especially glorious. I will watching this one avidly. |

|

|

|

#14 |

|

Member

Join Date: May 2012

Posts: 318

|

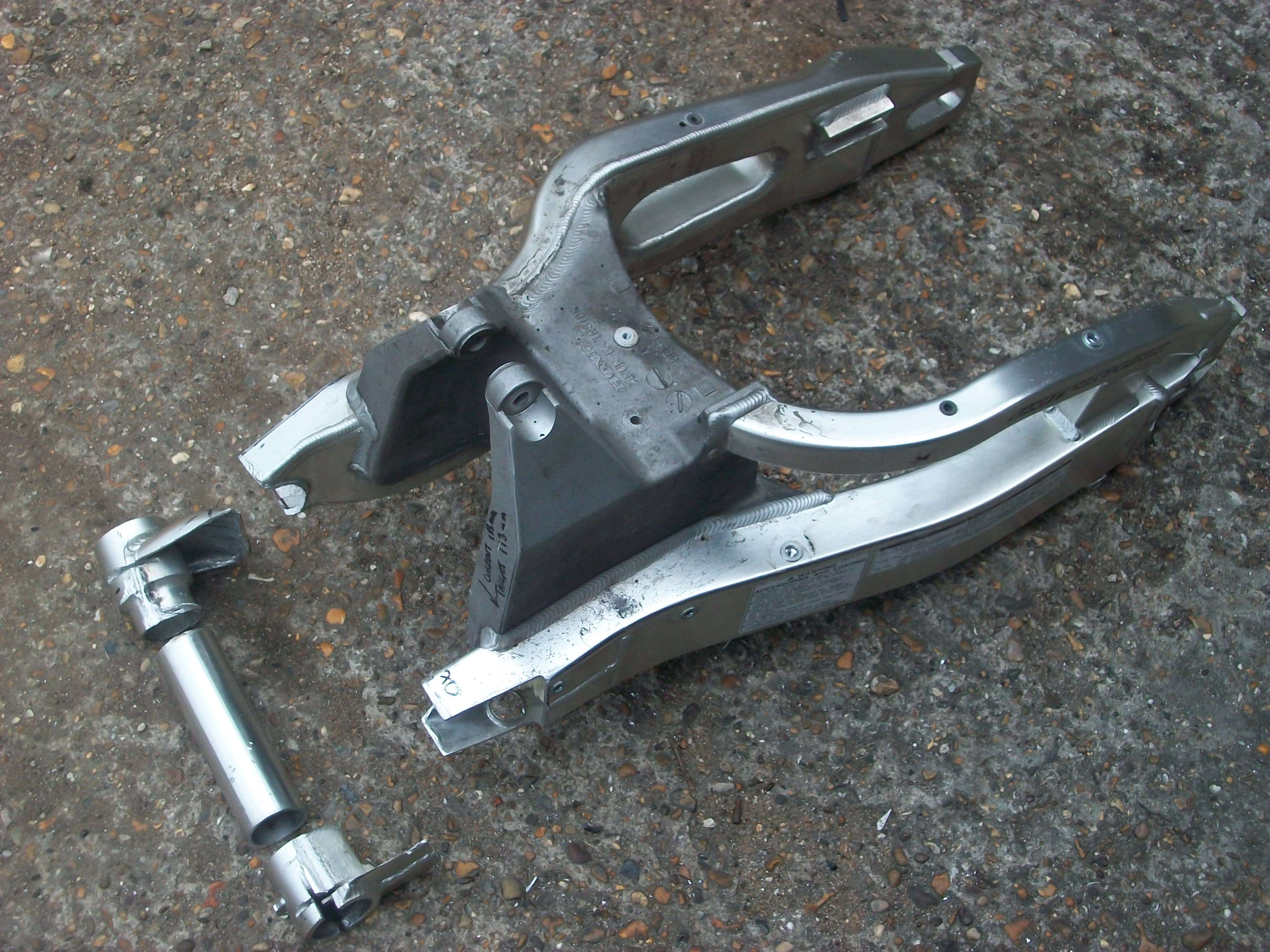

CBR swingarm cut away and now fitting into the narrow SV frame. I'm going to be machining the new bearing tube and few other parts over the next few weeks but the Olympics mean I'm going to be busy at work so these probably won't be ready until August.

|

|

|

|

|

|

#15 |

|

Guest

Posts: n/a

|

What area of mechanical engineering are you working in? I'm studying a degree in Mech Eng now, but just got a 12mth placement at Rolls Royce.

Shall be watching this project, looks good. |

|

|

|

#16 |

|

Member

Join Date: May 2012

Posts: 318

|

|

|

|

|

|

|

#17 |

|

Member

Join Date: May 2012

Posts: 318

|

It's been a while and I've not had a lot of time do any work on the bike due to working loads of hour for the 'lympics and dat, but I've made some progress over the last week or so...

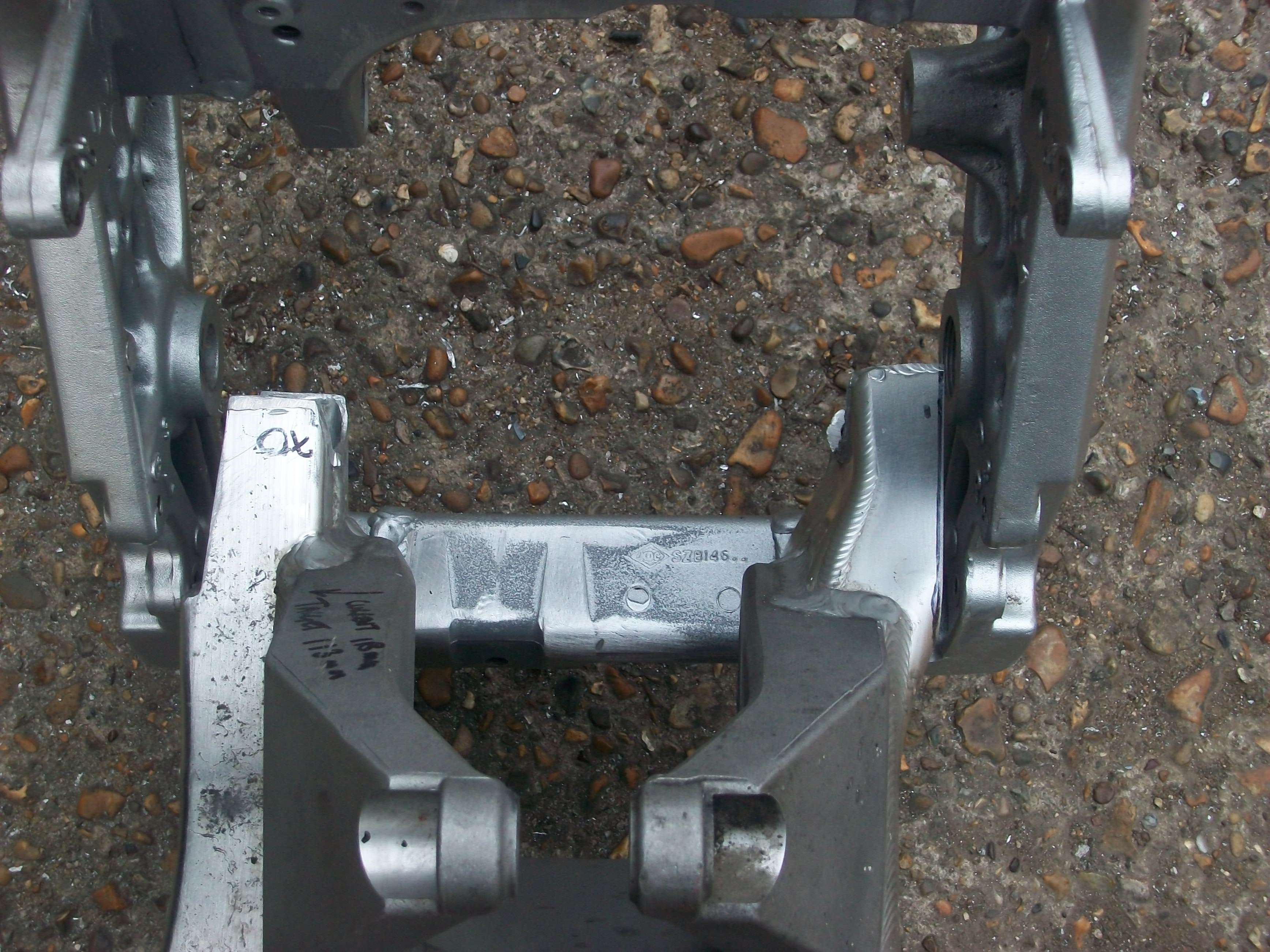

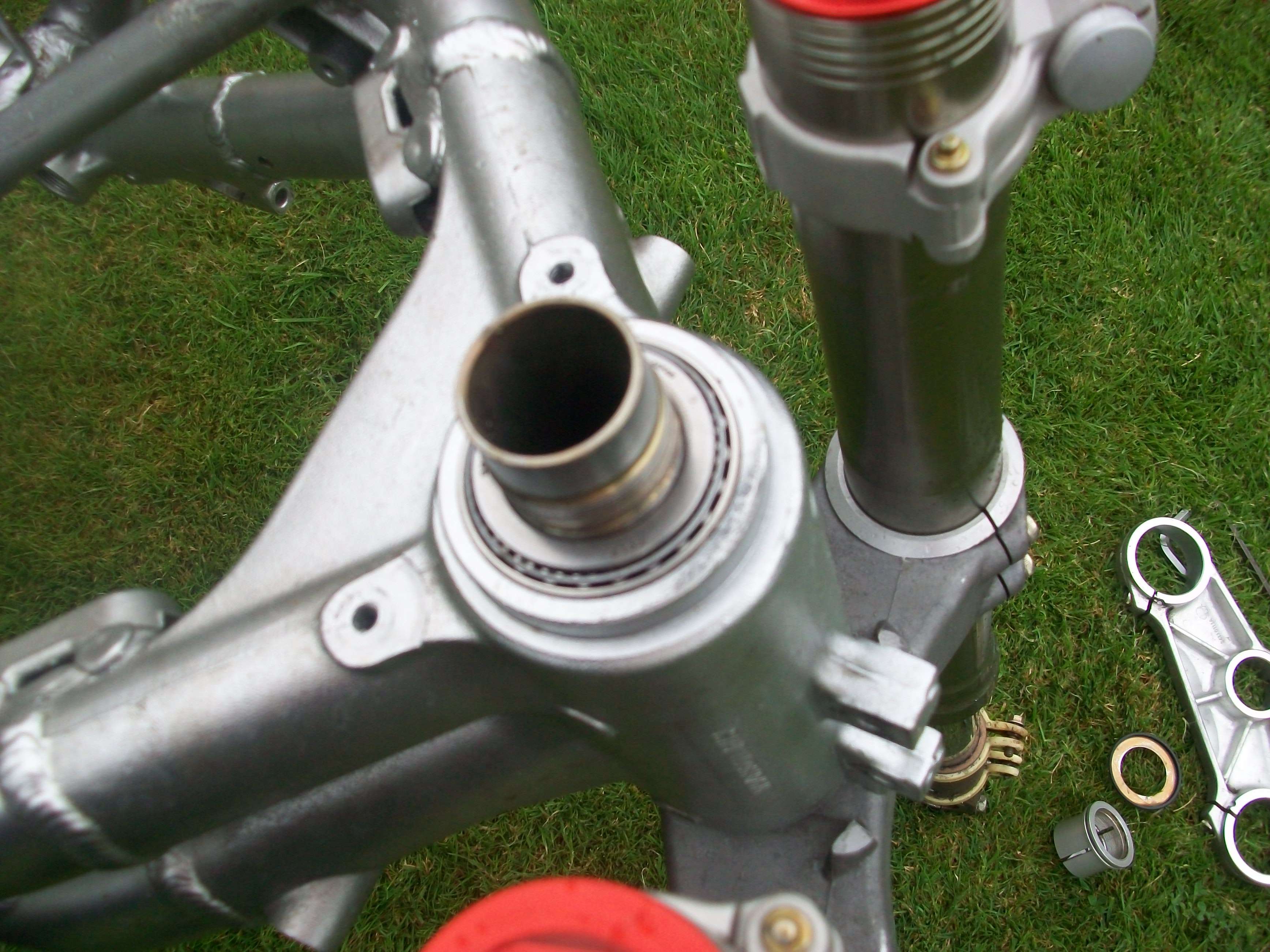

Started off simple with a spacer ring for the rear brake disc - spoked wheels are notoriously tight on clearance for brake calipers so the ring pushes the disc out enough for a Ducati 916 brembo rear caliper to fit.  Then machined out the upper headstock bearing to allow a larger diameter taper roller headstock bearing to be fitted - this was a bit dodgy to do, the frame only just fitted under the milling machine, it was strapped down with half a dozen ratchet straps and the headstock was balanced on a stack of odd offcuts of steel and ally to get it level and the feed rate was set as low as it could be to avoid the tool grabbing and flinging the frame across the workshop.  Made a new front axle out of EN24 to mate the smaller bearing dia of the SXV wheels with the Ducati forks and sleeve for the L/H fork leg to suit the new axle. Axle needs zinc coating. The threads should match the SXV axle nut...  The good news is I got my measurements right and there's now a fully fitted and functioning 916 front end in the SV frame and the SXV wheel is perfectly centred in the forks...  Only thing preventing the front brake from being fitted is disc alignment - the the disc is 6mm too far out at the moment, but the existing spacer ring can easily be machined down. New swingarm bearing tube is all done.    It matches the original CBR set up, just narrower. It's taped in place so that I can make templates from card for the plating pieces, ready for welding. There's also a pair of steel slugs that fit into the ends of the swingarm bearing tube and protect the bearing tube from distortion and weld penetration when it's being welded. The SV swingarm pivot axle is smaller dia than the CBR one, so I made a pair of sleeves to to take the inner races of the CBR swingarm bearings down to the right size for the SV pivot and made a new centre spacer tube to suit the SV axle and narrower bearing tube.  Next stage is to get the swingarm welded up. A local ally fabricator/welder who's got plenty of bike experience has agreed to supervise/teach me how to do it myself. |

|

|

|

|

|

#18 |

|

Guest

Posts: n/a

|

Looks very good, keep up the good work.

|

|

|

|

#19 |

|

Guest

Posts: n/a

|

|

|

|

|

#20 |

|

Guest

Posts: n/a

|

Keep up the good work, looking forward to watching this progress.

|

|

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| gsxr build | sv650nutter149 | Thames Valley | 21 | 12-05-10 07:22 AM |

| Hello! I have a few questions regarding a special build. | NcSv | SV Talk, Tuning & Tweaking | 50 | 08-09-09 11:47 PM |

| For Hovis-Gid-Stretchie-Wideboy , just a special thought for you guys on this special day | xXBADGERXx | Idle Banter | 21 | 24-07-09 04:26 PM |

| About to build one of these | SV-net | Idle Banter | 14 | 22-11-08 04:14 PM |

| VW build quality | kwak zzr | Idle Banter | 17 | 03-12-07 09:44 AM |